|

|

PDF ADNS-7530 Data sheet ( Hoja de datos )

| Número de pieza | ADNS-7530 | |

| Descripción | Integrated molded lead-frame DIP Sensor | |

| Fabricantes | PixArt | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de ADNS-7530 (archivo pdf) en la parte inferior de esta página. Total 30 Páginas | ||

|

No Preview Available !

Data Sheet

ADNS-7530

Integrated molded lead-frame DIP Sensor

Theory of Operation

The ADNS-7530 integrated molded lead-frame DIP

sensor comprises of sensor and VCSEL in a single

package.

The advanced class of VCSEL was engineered by PixArt

Imaging to provide a laser diode with a single lon-

gitudinal and a single transverse mode. In contrast to

most oxide-based single-mode VCSEL, this class of PixArt

VCSEL remains within single mode operation over a wide

range of output power. It has significantly lower power

consumption than a LED. It is an excellent choice for

optical navigation applications.

The sensor is based on Laser technology, which

measures changes in position by optically acquiring se-

quential surface images (frames) and mathematically

determining the direction and magnitude of movement.

It contains an Image Acquisition System (IAS), a Digital

Signal Processor (DSP), and a four wire serial port. The IAS

acquires microscopic surface images via the lens and il-

lumination system. These images are processed by the

DSP to determine the direction and distance of motion.

The DSP calculates the Δx and Δy relative displacement

values. An external microcontroller reads the Δx and Δy

information from the sensor serial port. The microcon-

troller then translates the data into PS2, USB, or RF signals

before sending them to the host PC or game console.

Features

• Wide operating voltage: 2.7V-3.6V

• Small form factor, integrated molded lead frame DIP

package

• Low power architecture

• Laser Technology

• Self-adjusting power-saving modes for longest battery

life

• High speed motion detection up to 30 ips and 8g

• Enhanced SmartSpeed self-adjusting frame rate for

optimum performance

• Motion detect pin output

• 12-bits motion data registers.

• Internal oscillator – no clock input needed.

• Selectable 400, 800, 1200, 1600, 2000 cpi resolution.

• Four wire serial port

• Minimal number of passive components

• Laser fault detect circuitry on-chip for Eye Safety

Compliance

• Advanced Technology VCSEL chip

• Single Mode Lasing operation

• 832-865 nm wavelength

Applications

• Laser Mice

• Optical trackballs

• Integrated input devices

• Battery-powered input devices

All rights strictly reserved any portion in this paper shall not be reproduced, copied or transformed to any other forms without permission.

PixArt Imaging Inc.

E-mail: [email protected]

1

1 page

PixArt Imaging Inc.

ADNS-7530 Integrated Molded Lead-Frame DIP Sensor

Assembly Recommendation

1. Insert the integrated molded lead-frame DIP

sensor and all other electrical components into the

application PCB.

2. This sensor package is only qualified for wave-solder

process.

3. Wave-solder the entire assembly in a no-wash solder

process utilizing a solder fixture. The solder fixture

is needed to protect the sensor during the solder

process. The fixture should be designed to expose

the sensor leads to solder while shielding the optical

aperture from direct solder contact.

4. Place the lens onto the base plate. Care must be taken

to avoid contamination on the optical surfaces.

5. Remove the protective kapton tapes from the optical

aperture of the sensor and VCSEL respectively. Care

must be taken to keep contaminants from entering

the aperture.

6. Insert the PCB assembly over the lens onto the base

plate. The sensor package should self-align to the lens.

The optical position reference for the PCB is set by the

base plate and lens. The alignment guide post of the

lens locks the lens and integrated molded lead-frame

DIP sensor together. Note that the PCB motion due to

button presses must be minimized to maintain optical

alignment.

7. Optional: The lens can be permanently locked to the

sensor package by melting the lens’ guide posts over

the sensor with heat staking process.

8. Tune the laser output power from the VCSEL to meet

the Eye Safe Class I Standard as detailed in the LASER

Power Adjustment Procedure.

9. Install the mouse top case. There must be a feature in

the top case (or other area) to press down onto the

sensor to ensure the sensor and lenses are interlocked

to the correct vertical height.

Design considerations for improving ESD Performance

For improved electrostatic discharge performance,

typical creepage and clearance distance are shown in

the table below. Assumption: base plate construction as

per the PixArt supplied IGES file and ADNS-6150, ADNS-

6160-001 or ADNS-6170-002 lens:

Lens ADNS-6150 ADNS-6160-001 ADNS-6170-002

Creepage 12.0 mm 13.50 mm

20.30 mm

Clearance 2.1 mm

1.28 mm

1.28 mm

Note that the lens material is polycarbonate and

therefore, cyanoacrylate based adhesives or other

adhesives that may damage the lens should NOT be

used.

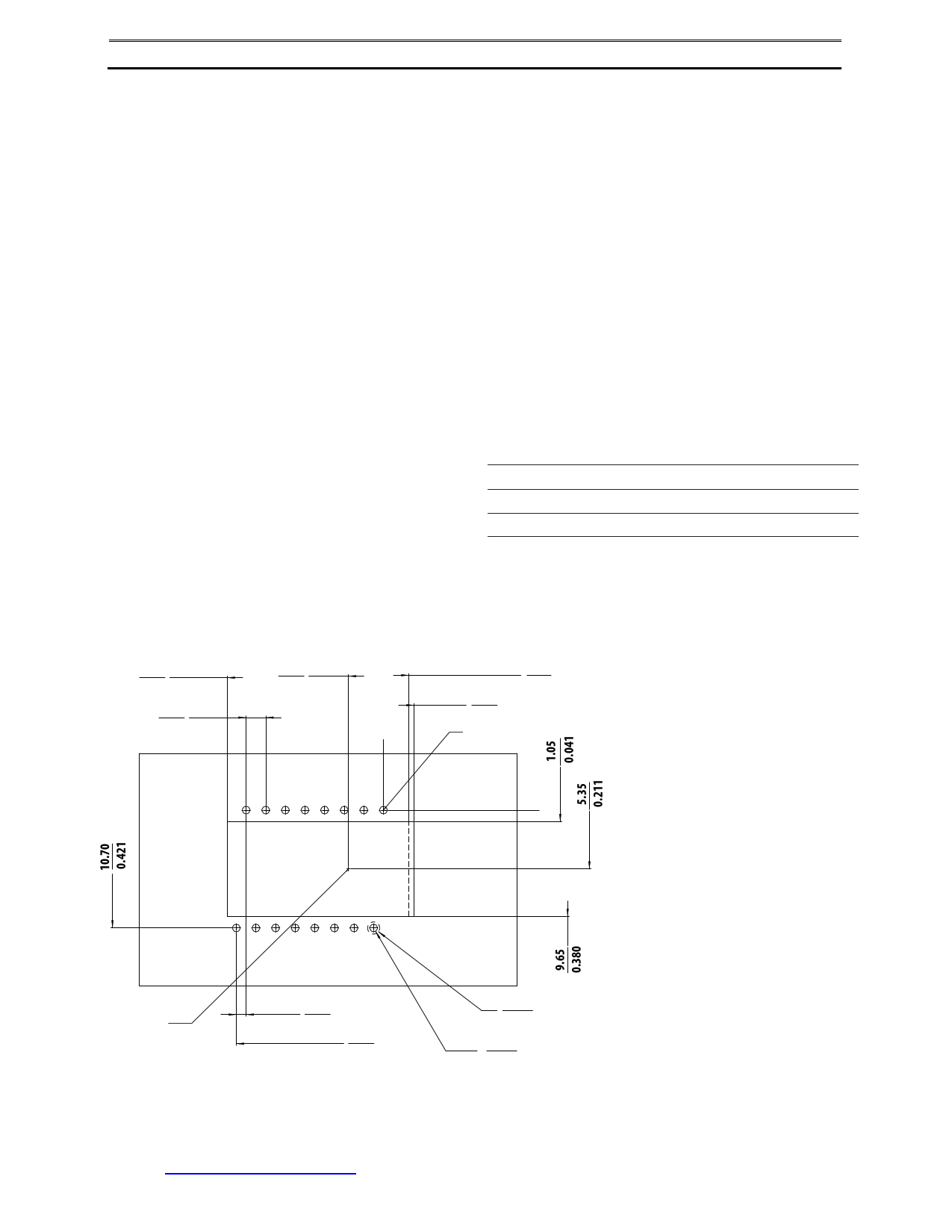

14.18

0.558

7X 1.78

0.070

3.18 Lens interference 2.31

0.125 0.091

(2.78)

0.110

0 Pin #1

0

Optical center

0.89

0.035

13.35

0.526

∅ 1.10

0.043

16X ∅ 0.70

0.028

Pad ring

Figure 5. Recommended PCB mechanical cutouts and spacing

All rights strictly reserved any portion in this paper shall not be reproduced, copied or transformed to any other forms without permission.

PixArt Imaging Inc.

5 Page

PixArt Imaging Inc.

ADNS-7530 Integrated Molded Lead-Frame DIP Sensor

Optical/Electrical Characteristics (at Tc = 5°C to 45°C):

VCSEL Die Source Marking

V = A,V

V=C

Parameter

Symbol Min Typ Max Min Typ Max Units Notes

Peak Wavelength

λ 832

865 832

865 nm

Maximum Radiant

Power

LOPmax

4.5

4.0 mW Maximum output power under

any condition. This is not a rec-

ommended operating condition

and does not meet eye safety

requirements.

Wavelength Temperature dλ/dT

Coefficient

0.065

0.065

nm/

ºC

Wavelength Current

Coefficient

dλ/dI

0.21

0.3 nm/

mA

Beam Divergence

θFW@1/

e^2

15

16 deg

Threshold Current

Slope Efficiency

Ith

SE

4.2

0.4

3.0 mA

0.35 W/A

Forward Voltage

VF

2.1 2.4

2.1 2.4 V At 500uW output power

Notes:

1. VCSELs are sorted into bins as specified in the power adjustment procedure. Appropriate binning register data values are used in the application

circuit to achieve the target output power. The VCSEL binning is marked on the integrated molded lead-frame DIP sensor package.

2. When driven with current or temperature range greater than specified in the power adjustment procedure section, eye safety limits may be

exceeded. The VCSEL should then be treated as a Class IIIb laser and as a potential eye hazard.

3. Over driving beyond LOPmax limit will cause the VCSEL to enter into an unstable region. Any LOP that exceeds this limit should not be taken as a

valid reference point in the laser power calibration process.

All rights strictly reserved any portion in this paper shall not be reproduced, copied or transformed to any other forms without permission.

PixArt Imaging Inc.

E-mail: [email protected]

11

11 Page | ||

| Páginas | Total 30 Páginas | |

| PDF Descargar | [ Datasheet ADNS-7530.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| ADNS-7530 | Integrated molded lead-frame DIP Sensor | AVAGO |

| ADNS-7530 | Integrated molded lead-frame DIP Sensor | PixArt |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |