|

|

PDF LTD141ECEF Data sheet ( Hoja de datos )

| Número de pieza | LTD141ECEF | |

| Descripción | TFT LCD Module | |

| Fabricantes | Toshiba | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de LTD141ECEF (archivo pdf) en la parte inferior de esta página. Total 30 Páginas | ||

|

No Preview Available !

To: Proview Electronics Co., Ltd.

APPROVAL SIGNATURE

SPECIFICATION

FOR

TOSHIBA MATSUSHITA DISPLAY TECHNOLOGY

TFT-LED MODULE

LTD141ECEF

SPECIFICATION No. :

LTD141ECEF

DATE OF ISSUE : 2003-04-15

(DATE OF EXPIRY : 2006-04-14)

H. Yamaguchi

General Manager

Quality Assurance Div.

<Engineering Department to contact as per SPECIFICATION>

TV/PC/Monitor-Use Marketing & Engineering Dept.

AVC-Use LTD Div.

Toshiba Matsushita Display Technology Co.,Ltd

1-9-2, Hatara-cho, Fukaya-shi, Saitama, 366-0032, JAPAN

1 page

Specification No.

Sheet 4

For Installation in Assembly

(1) The C-MOS LSIs used in LED module are very sensitive to ESD (Electro-static Discharge).

Ambient humidity of working area is recommended to be higher than 50%(RH).

Person handling LED modules should be grounded with wrist band. Tools like soldering iron and screw driver, and

working benches should be grounded.

The grounding should be done through a resistor of 0.5-1MΩ in order to prevent spark of ESD.

(2) When remove protection film from LED panel, peer off the film slowly (more than three seconds) from the edge of the

panel, using a soft-pointed tweezers covered by Teflon or adherent tape.

(3) Reduce dust level in working area. Especially the level of metal particle should be decreased.

Use finger stalls or soft and dust-free gloves in order to keep clean appearance of LED module when handled for

incoming inspection and assembly.

Σ(4) When LED panel becomes dirty, wipe off the panel surface softly with absorbent cotton or another soft cloth.

If necessary, breathe upon the panel surface and then wipe off immediately and softly again.

If the dirt can not be wiped off, absorbent cotton wetted a little with normal-hexane or petroleum benzine can be used for

wiping the panel.

Be careful not to spill this solvent into the inside of LED module. Driver ICs and PCB area used inside LED module may

be damaged by the solvent.

Σ(5) AVOID THE CONDENSATION OF WATER

Wipe off a spot or spots of water of mist and chemicals of mist on LED panel softly with absorbent cotton or another

cloth as soon as possible if happened, otherwise discoloration or stain may be caused. If water invade into LED module,

it may cause LED module damages.

Σ(6) Do not expose LED module to the gas (which is not normally contained in the atmosphere), it may cause mis-operation

or defects.

Σ(7) DO NOT APPLY MECHANICAL FORCES.

Do not bend or twist LED module even momentary when LED module is installed an enclosure of the system. Bending

or twisting LED module may cause its damages.

Make sure to design the enclosure that bending/twisting forces are not applied to LED module when it is installed in the

system.

Refrain from strong mechanical shock like dropping from the working bench or knocking against hard object.

These may cause glass of the panel crack, damage of FL or other mis-operation.

Σ(8) Refrain from excessive force like pushing the surface of LED panel. This may cause damage of the panel or electrical

parts on PCB.

Σ(9) Do not put heavy object such as tools, books, etc., and do not pile up LED modules.

Be careful not to touch surface of the polarizer laminated to the panel with any hard and sharp object. The polarizer is so

soft that it can easily scratched, even the protect film covers it.

(10) When inserting or disconnecting the connectors to LED module, be sure not to apply force against PCB, nor connecting

cables, otherwise internal connection of PCB and TAB drivers may be damaged.

Do not fasten screws while putting cables like those for interface or FL between LED module and the enclosure.

Make sure to insert the module FL connector to the inverter connector in correct position.

If incorrect, this may cause smoke or burn of electrical parts by high voltage of FL circuit.

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-04-15

Date: 2003-03-20

←# Special ←& Addition

New No.LTD141ECEF

Old No. NL-LTD141ECEE

← Change

5 Page

2.4 Electrical Specifications

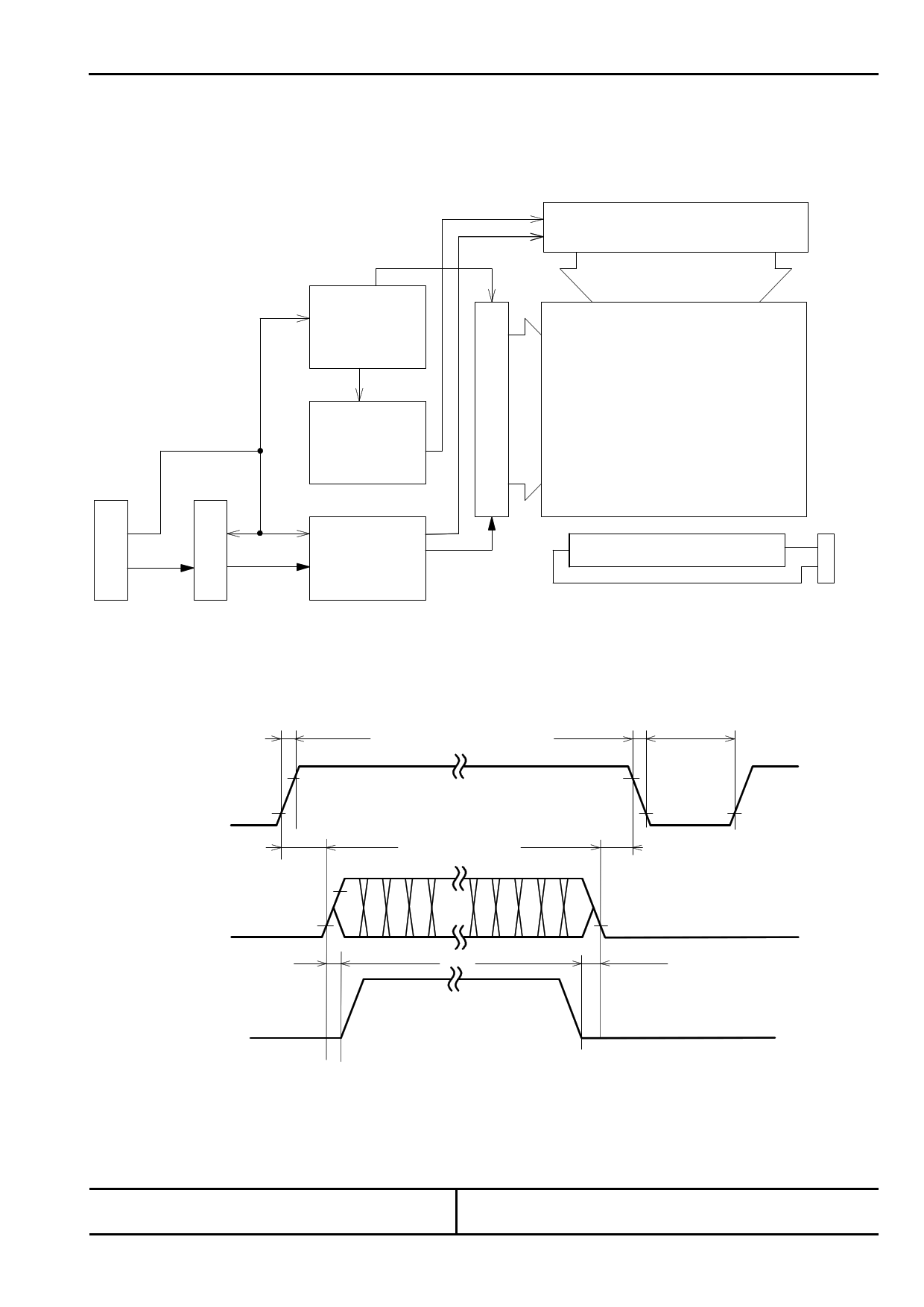

2.4.1 Circuit Diagram

Specification No.

Sheet 10

X-driver IC

CN1

DC/DC

converter

Gray scale

Manipulation

Voltage

Generation

Circuit

Panel

Controller

Liquid Crystal Panel

1024 x 768 pixels

Backlight

2.4.2 Sequence of Power Supplies and Signals

10ms (Max.)

20us (Min.)

3.0V

V DD 0.2V

65ms (Max.)

60ms (Min.)

10ms (Max.) 500ms (Min.)

3.0V

40ms (Max.)

0ms (Min.)

0.2V

0.2V

CLK-

IN0- - IN2-

CLK+

IN0+ - IN2+

10%

10%

10ms (Min.) 10ms (Min.)

Backlight

Toshiba Matsushita Display Technology Co.,Ltd

Date: 2003-04-15

Date: 2003-03-20

←# Special ←& Addition

New No.LTD141ECEF

Old No. NL-LTD141ECEE

← Change

11 Page | ||

| Páginas | Total 30 Páginas | |

| PDF Descargar | [ Datasheet LTD141ECEF.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| LTD141ECEF | TFT LCD Module | Toshiba |

| LTD141ECEP | TFT LCD Module | Toshiba |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |