|

|

PDF LTM4609 Data sheet ( Hoja de datos )

| Número de pieza | LTM4609 | |

| Descripción | 34VOUT High Efficiency Buck-Boost DC/DC uModule | |

| Fabricantes | Linear Dimensions Semiconductor | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de LTM4609 (archivo pdf) en la parte inferior de esta página. Total 24 Páginas | ||

|

No Preview Available !

www.DataSheet4U.com

LTM4609

36VIN, 34VOUT High Efficiency

Buck-Boost DC/DC µModule

FEATURES

n Single Inductor Architecture Allows VIN Above,

Below or Equal to VOUT

n Wide VIN Range: 4.5V to 36V

n Wide VOUT Range: 0.8V to 34V

n IOUT: 4A DC (10A DC in Buck Mode)

n Up to 98% Efficiency

n Current Mode Control

n Power Good Output Signal

n Phase-Lockable Fixed Frequency: 200kHz to 400kHz

n Ultra-Fast Transient Response

n Current Foldback Protection

n Output Overvoltage Protection

n Small, Low Profile Surface Mount LGA Package

(15mm × 15mm × 2.8mm)

APPLICATIONS

n Telecom, Servers and Networking Equipment

n Industrial and Automotive Equipment

n High Power Battery-Operated Devices

L, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

μModule is a trademark of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

DESCRIPTION

The LTM®4609 is a high efficiency switching mode buck-

boost power supply. Included in the package are the

switching controller, power FETs and support components.

Operating over an input voltage range of 4.5V to 36V, the

LTM4609 supports an output voltage range of 0.8V to

34V, set by a resistor. This high efficiency design delivers

up to 4A continuous current in boost mode (10A in buck

mode). Only the inductor, sense resistor, bulk input and

output capacitors are needed to finish the design.

The low profile package enables utilization of unused space

on the bottom of PC boards for high density point of load

regulation. The high switching frequency and current

mode architecture enable a very fast transient response

to line and load changes without sacrificing stability. The

LTM4609 can be frequency synchronized with an external

clock to reduce undesirable frequency harmonics.

Fault protection features include overvoltage and foldback

current protection. The DC/DC μModule™ is offered in a

small thermally enhanced 15mm × 15mm × 2.8mm LGA

package. The LTM4609 is Pb-free and RoHS compliant.

TYPICAL APPLICATION

30V/2A Buck-Boost DC/DC μModule with 5V to 36V Input

VIN

6.5V TO 36V

10μF

50V

ON/OFF

0.1μF

CLOCK SYNC

VIN PLLIN VOUT

FCB

RUN LTM4609

SW1

SW2

RSENSE

SENSE+

SS

SGND

SENSE–

PGND

VFB

5.6μH

R2

15mΩ

s2

2.74k

10μF +

50V

330μF

50V

VOUT

30V

2A

4609 TA01a

Efficiency and Power Loss

vs Input Voltage

99

6

98

5

97

4

96

95 3

94

2

93

1

92 EFFICIENCY

POWER LOSS

91 0

8 12 16 20 24 28 32 36

VIN (V)

4609 TA01b

4609f

1

1 page

www.DataSheet4U.com

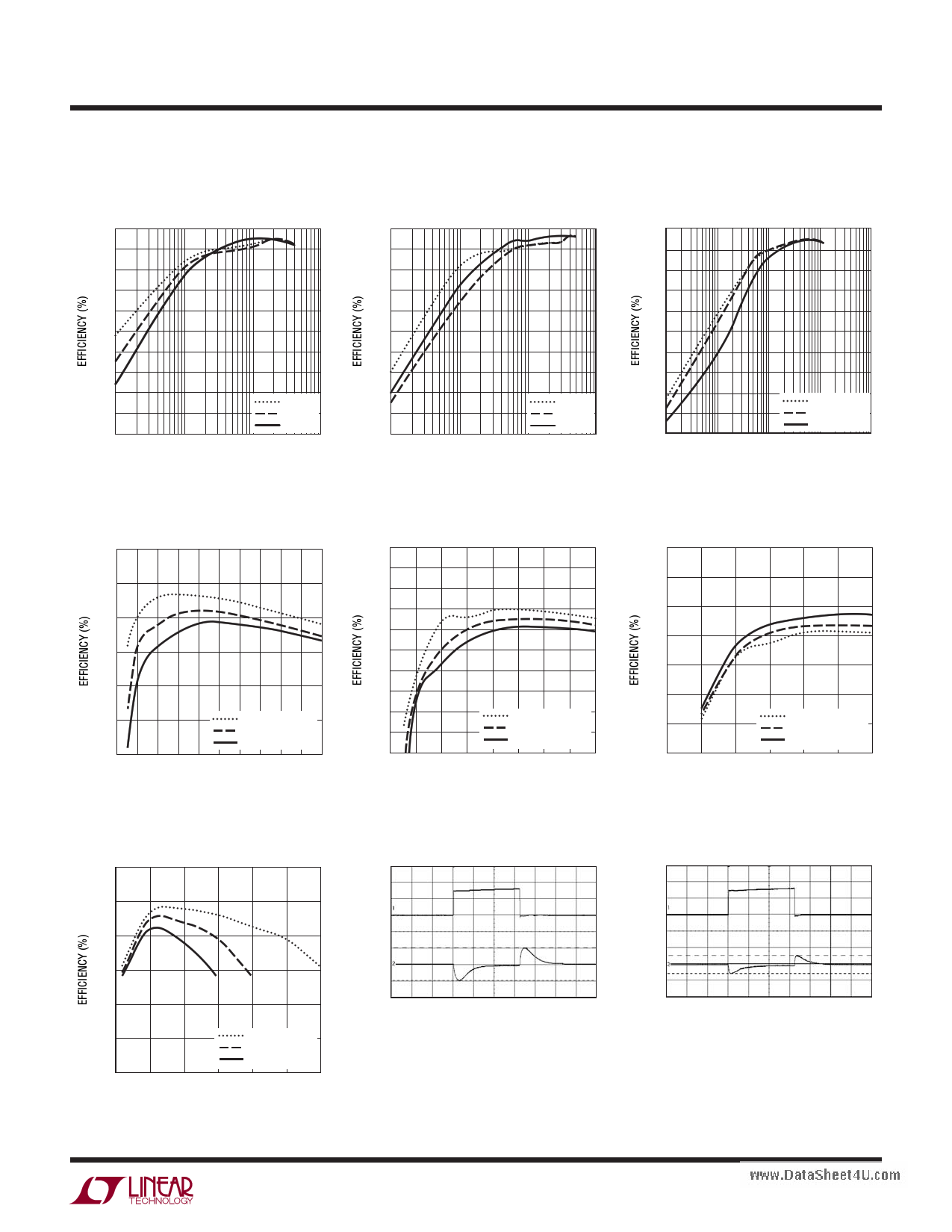

TYPICAL PERFORMANCE CHARACTERISTICS (Refer to Figure 18)

LTM4609

Efficiency vs Load Current

6VIN to 12VOUT

100

90

80

70

60

50

40

30

20

10

0

0.01

0.1 1

LOAD CURRENT (A)

BURST

DCM

CCM

10

4609 G01

Efficiency vs Load Current

12VIN to 12VOUT

100

90

80

70

60

50

40

30

20

10

0

0.01

0.1 1

LOAD CURRENT (A)

BURST

DCM

CCM

10

4609 G02

Efficiency vs Load Current

32VIN to 12VOUT

100

90

80

70

60

50

40

30

20

10

0

0.01

SKIP CYCLE

DCM

CCM

0.1 1 10

LOAD CURRENT (A)

100

4609 G03

Efficiency vs Load Current

3.3μH Inductor

100

95

90

85

80

75 12VIN TO 5VOUT

24VIN TO 5VOUT

32VIN TO 5VOUT

70

0 1 2 3 4 5 6 7 8 9 10

LOAD CURRENT (A)

4609 G04

Efficiency vs Load Current

5.6μH Inductor

100

99

98

97

96

95

94

93

92 28VIN to 20VOUT

91 32VIN to 20VOUT

36VIN to 20VOUT

90

012345678

LOAD CURRENT (A)

4609 G05

Efficiency vs Load Current

8μH Inductor

100

99

98

97

96

95

94

93

0

30VIN to 30VOUT

32VIN to 30VOUT

36VIN to 30VOUT

1234

LOAD CURRENT (A)

5

6

4609 G06

Efficiency vs Load Current

100

95

90

85

Transient Response from

6VIN to 12VOUT

IOUT

2A/DIV

VOUT

200mV/DIV

Transient Response from

12VIN to 12VOUT

IOUT

2A/DIV

VOUT

200mV/DIV

80

75

70

0

5VIN to 16VOUT

5VIN to 24VOUT

5VIN to 30VOUT

0.5 1 1.5 2 2.5

LOAD CURRENT (A)

3

4609 G07

200μs/DIV

4609 G08

LOAD STEP: 0A TO 3A AT CCM

OUTPUT CAPS: 4x 22μF CERAMIC CAPS AND

2x 180μF ELECTROLYTIC CAPS

2x 15mΩ SENSING RESISTORS

200μs/DIV

4609 G09

LOAD STEP: 0A TO 3A AT CCM

OUTPUT CAPS: 4x 22μF CERAMIC CAPS AND

2x 180μF ELECTROLYTIC CAPS

2x 15mΩ SENSING RESISTORS

4609f

5

5 Page

www.DataSheet4U.com

LTM4609

APPLICATIONS INFORMATION

ings are often based on temperature and hours of life. This

makes it advisable to properly derate the input capacitor,

or choose a capacitor rated at a higher temperature than

required. Always contact the capacitor manufacturer for

derating requirements.

Output Capacitors

In boost mode, the discontinuous current shifts from the

input to the output, so the output capacitor COUT must be

capable of reducing the output voltage ripple.

For boost and buck modes, the steady ripple due to charg-

ing and discharging the bulk capacitance is given by:

( )VRIPPLE,BOOST

=

IOUT(MAX) •

COUT

VOUT − VIN(MIN)

• VOUT • f

( )VRIPPLE,BUCK

=

VOUT

8 •L •

• VIN(MAX) − VOUT

COUT • VIN(MAX) • f2

The steady ripple due to the voltage drop across the ESR

(effective series resistance) is given by:

VESR,BUCK = ΔIL(MAX) • ESR

VESR,BOOST = IL(MAX) • ESR

The LTM4609 is designed for low output voltage ripple.

The bulk output capacitors defined as COUT are chosen

with low enough ESR to meet the output voltage ripple and

transient requirements. COUT can be the low ESR tantalum

capacitor, the low ESR polymer capacitor or the ceramic

capacitor. Multiple capacitors can be placed in parallel to

meet the ESR and RMS current handling requirements. The

typical capacitance is 300μF. Additional output filtering may

be required by the system designer, if further reduction of

output ripple or dynamic transient spike is required. Table 3

shows a matrix of different output voltages and output

capacitors to minimize the voltage droop and overshoot

at a current transient.

Inductor Selection

The inductor is chiefly decided by the required ripple cur-

rent and the operating frequency. The inductor current

ripple ΔIL is typically set to 20% to 40% of the maximum

inductor current. In the inductor design, the worst cases

in continuous mode are considered as follows:

( )LBOOST

≥

V2IN •

V 2OUT(MAX )

VOUT(MAX) −

• f •IOUT(MAX)

VIN

• Ripple%

( )LBUCK

≥

VOUT •

VIN(MAX) • f

VIN(MAX) −

• IOUT(MAX)

VOUT

• Ripple%

where:

f is operating frequency, Hz

Ripple% is allowable inductor current ripple, %

VOUT(MAX) is maximum output voltage, V

VIN(MAX) is maximum input voltage, V

VOUT is output voltage, V

IOUT(MAX) is maximum output load current, A

The inductor should have low DC resistance to reduce the

I2R losses, and must be able to handle the peak inductor

current without saturation. To minimize radiated noise,

use a toroid, pot core or shielded bobbin inductor. Please

refer to Table 3 for the recommended inductors for dif-

ferent cases.

RSENSE Selection and Maximum Output Current

RSENSE is chosen based on the required inductor current.

Since the maximum inductor valley current at buck mode

is much lower than the inductor peak current at boost

mode, different sensing resistors are suggested to use

in buck and boost modes.

The current comparator threshold sets the peak of the

inductor current in boost mode and the maximum inductor

valley current in buck mode. In boost mode, the allowed

maximum average load current is:

IOUT(MAX ,BOOST )

=

⎛

⎝⎜

160mV

RSENSE

−

ΔIL

2

⎞

⎠⎟

•

VIN

VOUT

where ΔIL is peak-to-peak inductor ripple current.

4609f

11

11 Page | ||

| Páginas | Total 24 Páginas | |

| PDF Descargar | [ Datasheet LTM4609.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| LTM4600 | High Efficiency DC/DC Module | Linear Technology |

| LTM4600HV | High Efficiency DC/DC uModule | Linear Technology |

| LTM4601 | step-down switch mode DC/DC power supply | Linear Technology |

| LTM4601-1 | step-down switch mode DC/DC power supply | Linear Technology |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |