|

|

PDF LM27964 Data sheet ( Hoja de datos )

| Número de pieza | LM27964 | |

| Descripción | White LED Driver System | |

| Fabricantes | National Semiconductor | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de LM27964 (archivo pdf) en la parte inferior de esta página. Total 14 Páginas | ||

|

No Preview Available !

August 2007

LM27964

White LED Driver System with I2C Compatible Brightness

Control

General Description

The LM27964 is a charge-pump-based white-LED driver that

is ideal for mobile phone display backlighting. The LM27964

can drive up to 6 LEDs in parallel along with multiple keypad

LEDs, with a total output current up to 180mA. Regulated in-

ternal current sources deliver excellent current matching in all

www.DataSheeLt4EUD.cso. m

The LED driver current sources are split into two indepen-

dently controlled groups. The primary group (4 LEDs) can be

used to backlight the main phone display and the second

group (2 LEDs) can be used to backlight a secondary display.

A single Keypad LED driver can power up to 16 keypad LEDs

with a current of 5mA each. The LM27964 has an I2C com-

patible interface that allows the user to independently control

the brightness on each bank of LEDs.

The LM27964 works off an extended Li-Ion input voltage

range (2.7V to 5.5V). The device provides excellent efficiency

without the use of an inductor by operating the charge pump

in a gain of 3/2, or in Pass-Mode. The proper gain for main-

taining current regulation is chosen, based on LED forward

voltage, so that efficiency is maximized over the input voltage

range.

The LM27964 is available in National's small 24-pin Leadless

Leadframe Package (LLP-24).

Features

■ 87% Peak LED Drive Efficiency

■ 0.2% Current Matching between Current Sinks

■ Drives 6 LEDs with up to 30mA per LED in two distinct

groups, for backlighting two displays (main LCD and sub

LCD)

■ Dedicated Keypad LED Driver with up to 80mA of drive

current

■ Independent Resistor-Programmable Current Settings

■ I2C Compatible Brightness Control Interface

■ Adaptive 1×- 3/2× Charge Pump

■ Extended Li-Ion Input: 2.7V to 5.5V

■ Small low profile industry standard leadless package, LLP

24 : (4mm x 4mm x 0.8mm)

■ LM27964SQ-I LED PWM frequency = 10kHz,

LM27964SQ-C LED PWM frequency = 23kHz

Applications

■ Mobile Phone Display Lighting

■ Mobile Phone Keypad Lighting

■ PDAs Backlighting

■ General LED Lighting

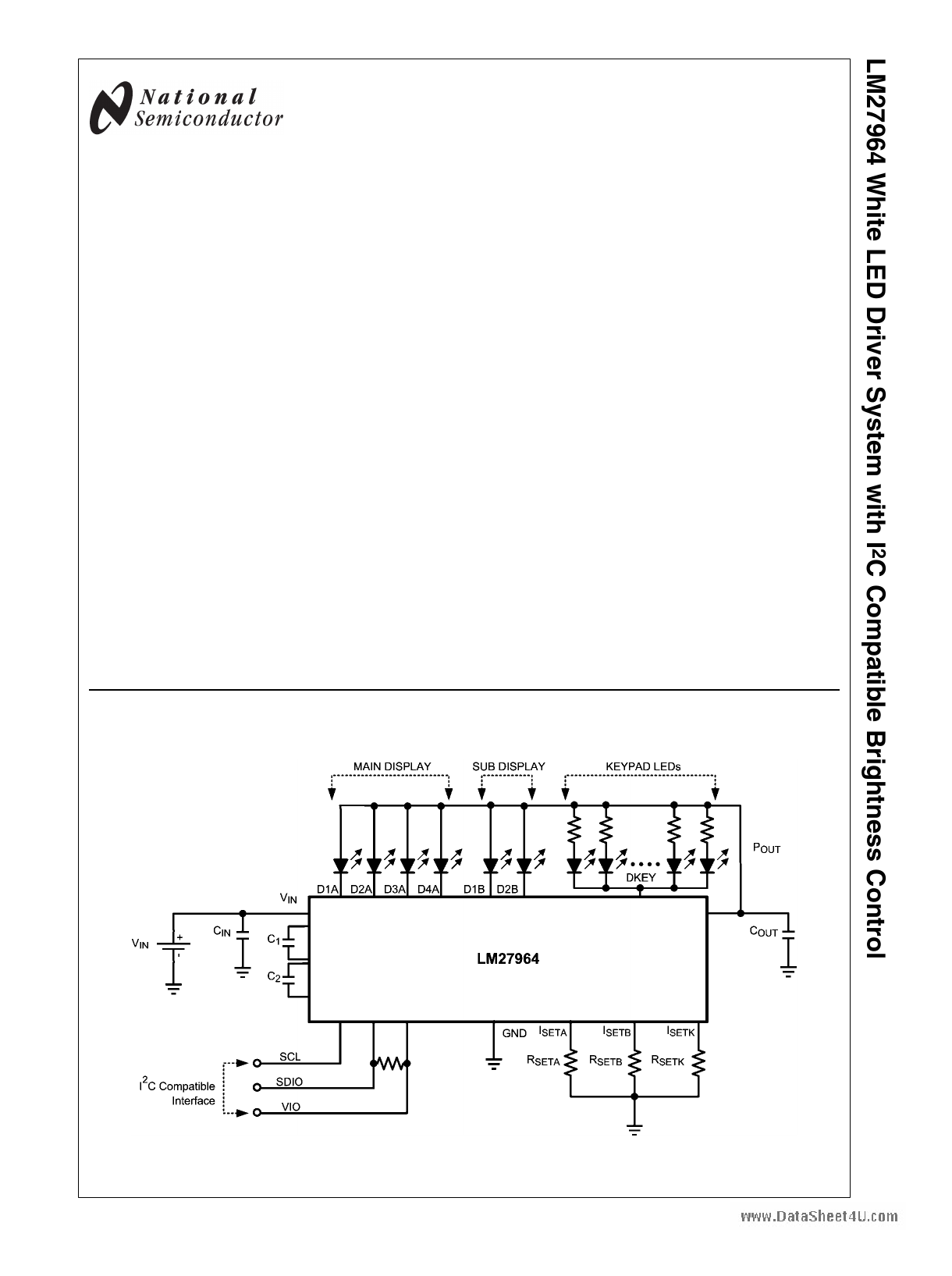

Typical Application Circuit

© 2007 National Semiconductor Corporation 201381

20138101

www.national.com

1 page

Note 7: Junction-to-ambient thermal resistance is highly dependent on application and board layout. In applications where high maximum power dissipation

exists, special care must be paid to thermal dissipation issues in board design. For more information, please refer to National Semiconductor Application Note

1187: Leadless Leadframe Package (AN-1187).

Note 8: Min and Max limits are guaranteed by design, test, or statistical analysis. Typical numbers are not guaranteed, but do represent the most likely norm.

Note 9: CIN, CPOUT, C1, and C2 : Low-ESR Surface-Mount Ceramic Capacitors (MLCCs) used in setting electrical characteristics

Note 10: The maximum total output current for the LM27964 should be limited to 180mA. The total output current can be split among any of the three banks

(IDxA = IDxB = 30mA Max., IDKEY = 80mA Max.). Under maximum output current conditions, special attention must be given to input voltage and LED forward

voltage to ensure proper current regulation. See the Maximum Output Current section of the datasheet for more information.

Note 11: For each IDxx output pin, headroom voltage is the voltage across the internal current sink connected to that pin. For Group A and B outputs, VHR =

VOUT -VDxx. If headroom voltage requirement is not met, LED current regulation will be compromised.

Note 12: For the two groups of outputs on a part (BankA and BankB), the following are determined: the maximum output current in the group (MAX), the minimum

output current in the group (MIN), and the average output current of the group (AVG). For each group, two matching numbers are calculated: (MAX-AVG)/AVG

and (AVG-MIN)/AVG. The largest number of the two (worst case) is considered the matching figure for the bank. The matching figure for a given part is considered

to be the highest matching figure of the two banks. The typical specification provided is the most likely norm of the matching figure for all parts.

Note 13: SCL and SDIO should be glitch-free in order for proper brightness control to be realized.

Block Diagram

www.DataSheet4U.com

20138103

5 www.national.com

5 Page

forward voltage. Excessive power dissipation may also limit

output current capability of an application.

Total Output Current Capability

The maximum output current that can be drawn from the

LM27964 is 180mA. Each driver bank has a maximum allotted

current per Dxx sink that must not be exceeded.

DRIVER TYPE

MAXIMUM Dxx CURRENT

DxA 30mA per DxA Pin

DxB 30mA per DxB Pin

DKEY

80mA

The 180mA load can be distributed in many different config-

urations. Special care must be taken when running the

LM27964 at the maximum output current to ensure proper

functionality.

www.DataPSAheReAt4LUL.EcoLmCONNECTED OUTPUTS

Outputs D1A-4A or D1B-D2B may be connected together to

drive one or two LEDs at higher currents. In such a configu-

ration, all four parallel current sinks (BankA) of equal value

can drive a single LED. The LED current programmed for

BankA should be chosen so that the current through each of

the outputs is programmed to 25% of the total desired LED

current. For example, if 60mA is the desired drive current for

a single LED, RSETA should be selected such that the current

through each of the current sink inputs is 15mA. Similarly, if

two LEDs are to be driven by pairing up the D1A-4A inputs

(i.e D1A-2A, D3A-4A), RSETA should be selected such that the

current through each current sink input is 50% of the desired

LED current. The same RSETx selection guidelines apply to

BankB diodes.

Connecting the outputs in parallel does not affect internal op-

eration of the LM27964 and has no impact on the Electrical

Characteristics and limits previously presented. The available

diode output current, maximum diode voltage, and all other

specifications provided in the Electrical Characteristics table

apply to this parallel output configuration, just as they do to

the standard 4-LED application circuit.

Both BankA and BankB utilize LED forward voltage sensing

circuitry on each Dxx pin to optimize the charge-pump gain

for maximum efficiency. Due to the nature of the sensing cir-

cuitry, it is not recommended to leave any of the DxA or DxB

pins unused if either diode bank is going to be used during

normal operation. Leaving DxA and/or DxB pins unconnected

will force the charge-pump into 3/2× mode over the entire

VIN range negating any efficiency gain that could be achieve

by switching to 1× mode at higher input voltages.

Care must be taken when selecting the proper RSETx value.

The current on any Dxx pin must not exceed the maximum

current rating for any given current sink pin.

POWER EFFICIENCY

Efficiency of LED drivers is commonly taken to be the ratio of

power consumed by the LEDs (PLED) to the power drawn at

the input of the part (PIN). With a 1.5x/1x charge pump, the

input current is equal to the charge pump gain times the output

current (total LED current). The efficiency of the LM27964 can

be predicted as follows:

PLEDTOTAL = (VLEDA × NA × ILEDA) +

(VLEDB × NB × ILEDB) + (VLEDK × NK × ILEDK)

PIN = VIN × IIN

PIN = VIN × (GAIN × ILEDTOTAL + IQ)

E = (PLEDTOTAL ÷ PIN)

It is also worth noting that efficiency as defined here is in part

dependent on LED voltage. Variation in LED voltage does not

affect power consumed by the circuit and typically does not

relate to the brightness of the LED. For an advanced analysis,

it is recommended that power consumed by the circuit (VIN x

IIN) be evaluated rather than power efficiency.

POWER DISSIPATION

The power dissipation (PDISS) and junction temperature (TJ)

can be approximated with the equations below. PIN is the

power generated by the 1.5x/1x charge pump, PLED is the

power consumed by the LEDs, TA is the ambient temperature,

and θJA is the junction-to-ambient thermal resistance for the

LLP-24 package. VIN is the input voltage to the LM27964,

VLED is the nominal LED forward voltage, N is the number of

LEDs and ILED is the programmed LED current.

PDISS = PIN - PLEDA - PLEDB - PLEDK

PDISS= (GAIN × VIN × ILEDA + LEDB + LEDK) - (VLEDA × NA ×

ILEDA) -

(VLEDB × NB × ILEDB) - (VLEDK × NK × ILEDK)

TJ = TA + (PDISS x θJA)

The junction temperature rating takes precedence over the

ambient temperature rating. The LM27964 may be operated

outside the ambient temperature rating, so long as the junc-

tion temperature of the device does not exceed the maximum

operating rating of 100°C. The maximum ambient tempera-

ture rating must be derated in applications where high power

dissipation and/or poor thermal resistance causes the junc-

tion temperature to exceed 100°C.

THERMAL PROTECTION

Internal thermal protection circuitry disables the LM27964

when the junction temperature exceeds 170°C (typ.). This

feature protects the device from being damaged by high die

temperatures that might otherwise result from excessive pow-

er dissipation. The device will recover and operate normally

when the junction temperature falls below 165°C (typ.). It is

important that the board layout provide good thermal conduc-

tion to keep the junction temperature within the specified

operating ratings.

CAPACITOR SELECTION

The LM27964 requires 4 external capacitors for proper oper-

ation (C1 = C2 = 1µF, CIN = COUT = 2.2µF). Surface-mount

multi-layer ceramic capacitors are recommended. These ca-

pacitors are small, inexpensive and have very low equivalent

series resistance (ESR <20mΩ typ.). Tantalum capacitors,

OS-CON capacitors, and aluminum electrolytic capacitors are

not recommended for use with the LM27964 due to their high

ESR, as compared to ceramic capacitors.

For most applications, ceramic capacitors with X7R or X5R

temperature characteristic are preferred for use with the

LM27964. These capacitors have tight capacitance tolerance

(as good as ±10%) and hold their value over temperature

(X7R: ±15% over -55°C to 125°C; X5R: ±15% over -55°C to

85°C).

Capacitors with Y5V or Z5U temperature characteristic are

generally not recommended for use with the LM27964. Ca-

pacitors with these temperature characteristics typically have

wide capacitance tolerance (+80%, -20%) and vary signifi-

cantly over temperature (Y5V: +22%, -82% over -30°C to

+85°C range; Z5U: +22%, -56% over +10°C to +85°C range).

Under some conditions, a nominal 1µF Y5V or Z5U capacitor

could have a capacitance of only 0.1µF. Such detrimental de-

viation is likely to cause Y5V and Z5U capacitors to fail to

11 www.national.com

11 Page | ||

| Páginas | Total 14 Páginas | |

| PDF Descargar | [ Datasheet LM27964.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| LM2796 | Dual-Display White LED Driver with 3/2x Switched Capacitor Boost | National Semiconductor |

| LM2796 | LM2796 Dual-Display White LED Driver with 3/2x Switched Capacitor Boost (Rev. A) | Texas Instruments |

| LM27961 | LM27961 Dual-Display White LED Driver with 3/2x Switched Capacitor Boost (Rev. A) | Texas Instruments |

| LM27961 | Dual-Display White | National Semiconductor |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |