|

|

PDF HCPL-7710 Data sheet ( Hoja de datos )

| Número de pieza | HCPL-7710 | |

| Descripción | 40 ns Propagation Delay / CMOS Optocoupler | |

| Fabricantes | Hewlett-Packard | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de HCPL-7710 (archivo pdf) en la parte inferior de esta página. Total 17 Páginas | ||

|

No Preview Available !

Agilent HCPL-7710, HCPL-0710

40 ns Propagation Delay,

CMOS Optocoupler

Data Sheet

Description

Available in either an 8-pin DIP or

SO-8 package style respectively,

the HCPL-7710 or HCPL-0710

optocouplers utilize the latest

CMOS IC technology to achieve

outstanding performance with

very low power consumption. The

HCPL-x710 require only two

bypass capacitors for complete

CMOS compatibility.

Basic building blocks of the

HCPL-x710 are a CMOS LED

driver IC, a high speed LED and a

CMOS detector IC. A CMOS logic

input signal controls the LED

driver IC which supplies current

to the LED. The detector IC

incorporates an integrated

photodiode, a high-speed

transimpedance amplifier, and a

voltage comparator with an

output driver.

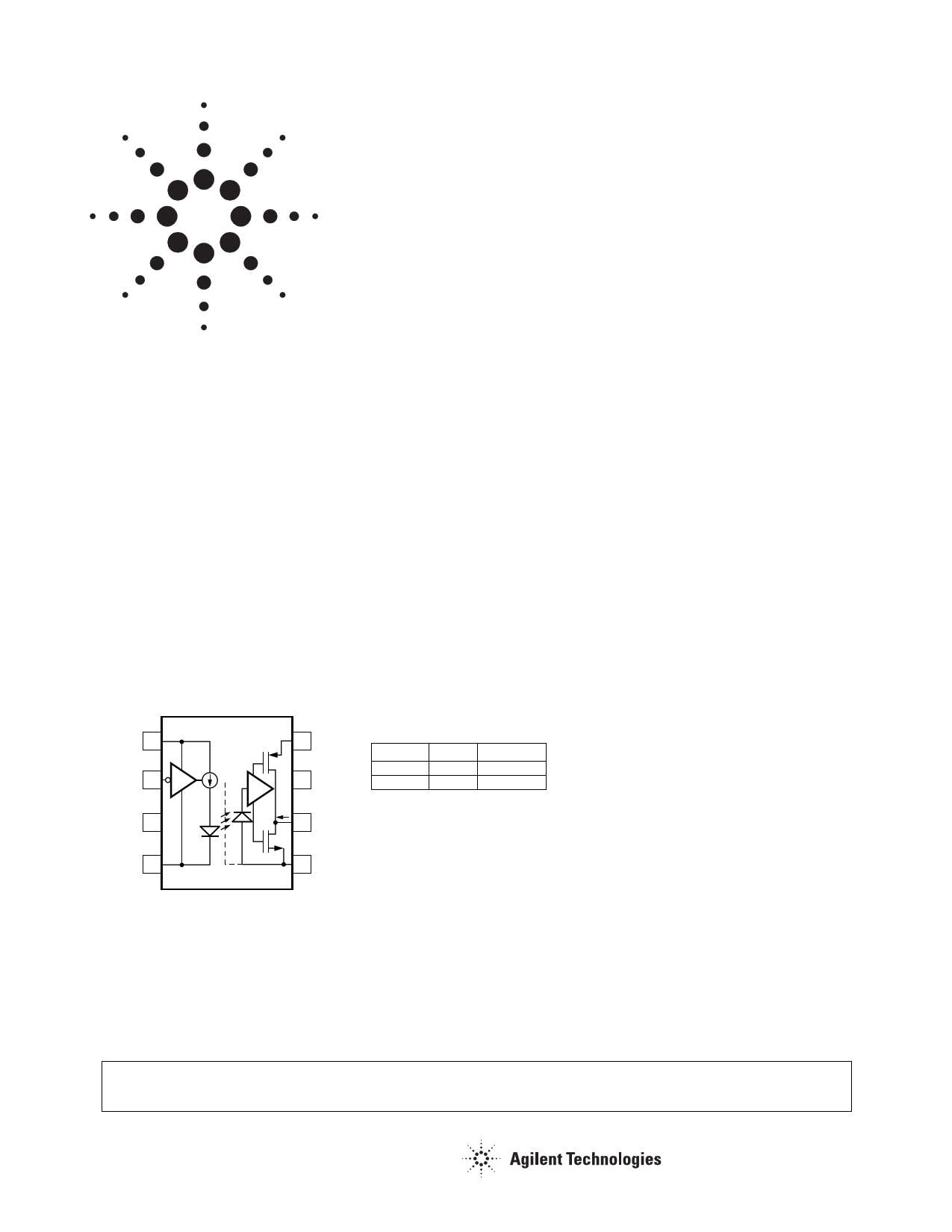

Functional Diagram

**VDD1 1

VI 2

*3

GND1 4

LED1

SHIELD

8 VDD2**

7 NC*

IO

6 VO

TRUTH TABLE

(POSITIVE LOGIC)

VI, INPUT

H

L

LED1

OFF

ON

VO, OUTPUT

H

L

5 GND2

Features

• +5 V CMOS compatibility

• 8 ns maximum pulse width

distortion

• 20 ns maximum prop. delay skew

• High speed: 12 Mbd

• 40 ns maximum prop. delay

• 10 kV/µs minimum common mode

rejection

• -40°C to 100°C temperature range

• Safety and regulatory approvals

UL Recognized

3750 V rms for 1 min. per

UL 1577

CSA Component Acceptance

Notice #5

IEC/EN/DIN EN 60747-5-2

– VIORM = 630 Vpeak for

HCPL-7710 Option 060

– VIORM = 560 Vpeak for

HCPL-0710 Option 060

Applications

• Digital fieldbus isolation:

DeviceNet, SDS, Profibus

• AC plasma display panel level

shifting

• Multiplexed data transmission

• Computer peripheral interface

• Microprocessor system interface

* Pin 3 is the anode of the internal LED and must be left unconnected for guaranteed data sheet

performance. Pin 7 is not connected internally.

** A 0.1 µF bypass capacitor must be connected between pins 1 and 4, and 5 and 8.

CAUTION: It is advised that normal static precautions be taken in handling and assembly of this

component to prevent damage and/or degradation which may be induced by ESD.

1 page

IEC/EN/DIN EN 60747-5-2 Insulation Related Characteristics (Option 060)

Description

Installation classification per DIN VDE 0110/1.89, Table 1

for rated mains voltage ≤150 V rms

for rated mains voltage ≤300 V rms

for rated mains voltage ≤450 V rms

Climatic Classification

Pollution Degree (DIN VDE 0110/1.89)

Maximum Working Insulation Voltage

Input to Output Test Voltage, Method b†

VIORM x 1.875 = VPR, 100% Production

Test with tm = 1 sec, Partial Discharge < 5 pC

Input to Output Test Voltage, Method a†

VIORM x 1.5 = VPR, Type and Sample Test,

tm = 60 sec, Partial Discharge < 5 pC

Highest Allowable Overvoltage†

(Transient Overvoltage, tini = 10 sec)

Safety Limiting Values

(Maximum values allowed in the event of a failure,

also see Thermal Derating curve, Figure 11.)

Case Temperature

Input Current

Output Power

Insulation Resistance at TS, V10 = 500 V

Symbol

VIORM

VPR

VPR

VIOTM

TS

IS,INPUT

PS,OUTPUT

RIO

HCPL-7710

Option 060

I-IV

I-IV

I-III

55/100/21

2

630

1181

945

6000

175

230

600

≥109

HCPL-0710

Option 060

I-IV

I-III

55/100/21

2

560

1050

Units

V peak

V peak

840 V peak

4000 V peak

150 °C

150 mA

600 mW

≥109

Ω

†Refer to the front of the optocoupler section of the Isolation and Control Component Designer’s Catalog, under Product Safety Regulations section

IEC/EN/DIN EN 60747-5-2, for a detailed description.

Note: These optocouplers are suitable for “safe electrical isolation” only within the safety limit data. Maintenance of the safety data shall be ensured

by means of protective circuits.

Note: The surface mount classification is Class A in accordance with CECC 00802.

Absolute Maximum Ratings

Parameter

Storage Temperature

Ambient Operating Temperature

Supply Voltages

Input Voltage

Output Voltage

Input Current

Average Output Current

Lead Solder Temperature

Solder Reflow Temperature Profile

Symbol Min. Max.

Units

TS

–55 125

°C

TA –40 +100 °C

VDD1, VDD2

0

6.0

Volts

VI

–0.5

VDD1 +0.5

Volts

VO

–0.5

VDD2 +0.5

Volts

II

–10 +10

mA

IO 10 mA

260°C for 10 sec., 1.6 mm below seating plane

See Solder Reflow Temperature Profile Section

Figure

Recommended Operating Conditions

Parameter

Ambient Operating Temperature

Supply Voltages

Logic High Input Voltage

Logic Low Input Voltage

Input Signal Rise and Fall Times

Symbol

TA

VDD1, VDD2

VIH

VIL

tr, tf

Min.

–40

4.5

2.0

0.0

Max.

+100

5.5

VDD1

0.8

1.0

Units

°C

V

V

V

ms

Figure

1, 2

5

5 Page

Digital Field Bus Communication

Networks

To date, despite its many draw-

backs, the 4 - 20 mA analog

current loop has been the most

widely accepted standard for

implementing process control

systems. In today’s manufacturing

environment, however, automated

systems are expected to help

manage the process, not merely

monitor it. With the advent of

digital field bus communication

networks such as DeviceNet,

PROFIBUS, and Smart

Distributed Systems (SDS), gone

are the days of constrained

information. Controllers can now

receive multiple readings from

field devices (sensors, actuators,

etc.) in addition to diagnostic

information.

The physical model for each of

these digital field bus communica-

tion networks is very similar as

shown in Figure 17. Each includes

one or more buses, an interface

unit, optical isolation, transceiver,

and sensing and/or actuating

devices.

CONTROLLER

BUS

INTERFACE

OPTICAL

ISOLATION

TRANSCEIVER

FIELD BUS

TRANSCEIVER

OPTICAL

ISOLATION

BUS

INTERFACE

TRANSCEIVER

OPTICAL

ISOLATION

BUS

INTERFACE

TRANSCEIVER

OPTICAL

ISOLATION

BUS

INTERFACE

TRANSCEIVER

OPTICAL

ISOLATION

BUS

INTERFACE

DEVICE

CONFIGURATION

MOTOR

STARTER

Figure 17. Typical field bus communication physical model.

XXXXXX

YYY

MOTOR

CONTROLLER

SENSOR

Optical Isolation for Field Bus

Networks

To recognize the full benefits of

these networks, each recommends

providing galvanic isolation using

Agilent optocouplers. Since

network communication is bi-

directional (involving receiving

data from and transmitting data

onto the network), two Agilent

optocouplers are needed. By

providing galvanic isolation, data

integrity is retained via noise

reduction and the elimination of

false signals. In addition, the

network receives maximum

protection from power system

faults and ground loops.

Within an isolated node, such as

the DeviceNet Node shown in

Figure 18, some of the node’s

components are referenced to a

ground other than V- of the

network. These components could

include such things as devices

with serial ports, parallel ports,

RS232 and RS485 type ports. As

shown in Figure 18, power from

the network is used only for the

transceiver and input (network)

side of the optocouplers.

Isolation of nodes connected to

any of the three types of digital

field bus networks is best

achieved by using the HCPL-x710

optocouplers. For each network,

the HCPL-x710 satisify the critical

propagation delay and pulse

width distortion requirements

over the temperature range of 0°C

to +85°C, and power supply

voltage range of 4.5 V to 5.5 V.

11

11 Page | ||

| Páginas | Total 17 Páginas | |

| PDF Descargar | [ Datasheet HCPL-7710.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| HCPL-7710 | 40 ns Propagation Delay / CMOS Optocoupler | Hewlett-Packard |

| HCPL-7710 | 40 ns Propagation Delay / CMOS Optocoupler | Avago |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |