|

|

PDF TDA7073 Data sheet ( Hoja de datos )

| Número de pieza | TDA7073 | |

| Descripción | Dual BTL power driver | |

| Fabricantes | NXP Semiconductors | |

| Logotipo | ||

Hay una vista previa y un enlace de descarga de TDA7073 (archivo pdf) en la parte inferior de esta página. Total 16 Páginas | ||

|

No Preview Available !

INTEGRATED CIRCUITS

DATA SHEET

TDA7073A; TDA7073AT

Dual BTL power driver

Product specification

Supersedes data of 1994 July

File under Integrated Circuits, IC01

1999 Aug 30

1 page

Philips Semiconductors

Dual BTL power driver

Product specification

TDA7073A; TDA7073AT

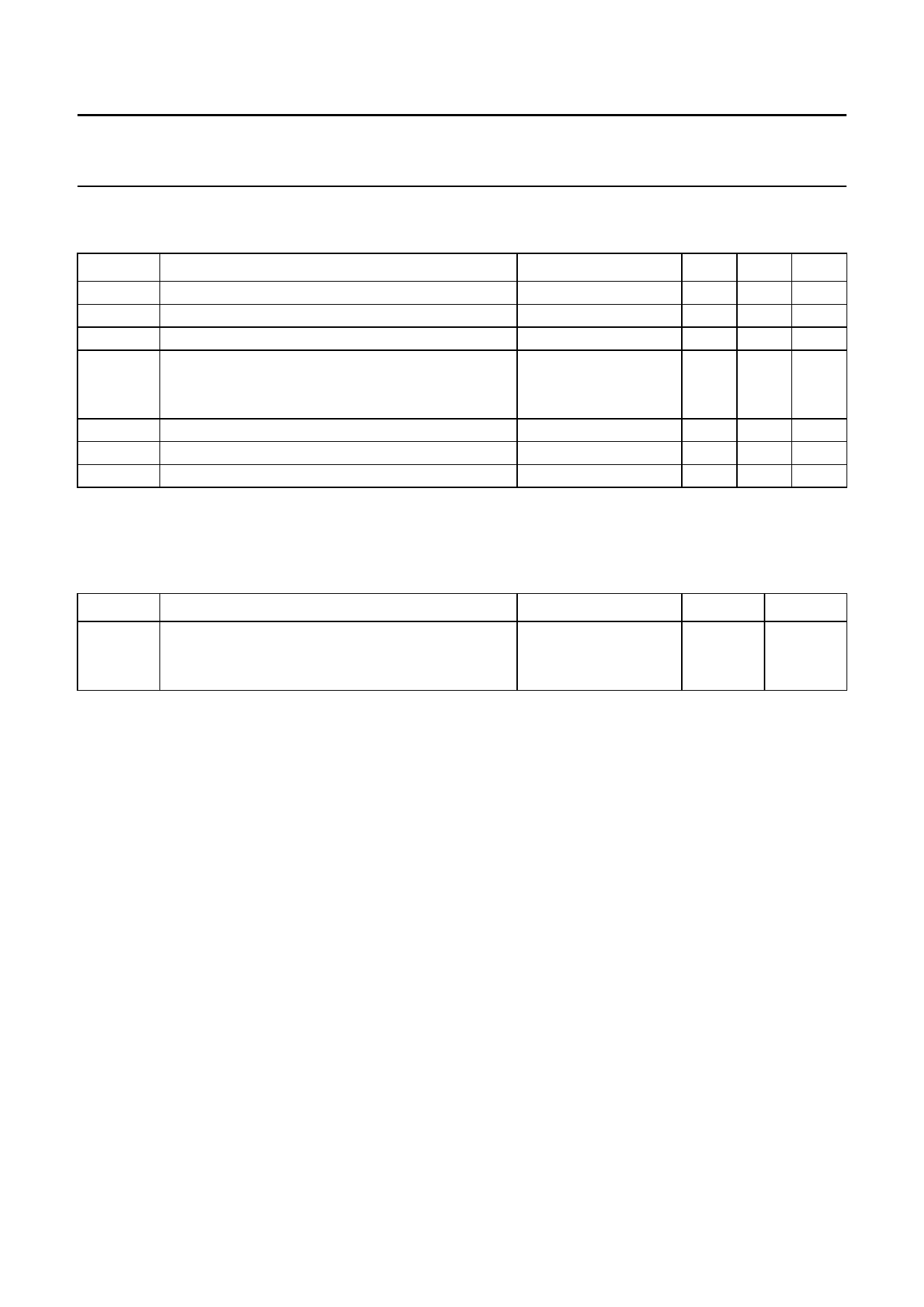

LIMITING VALUES

In accordance with the Absolute Maximum System (IEC 134).

SYMBOL

PARAMETER

VP

IORM

IOSM

Ptot

positive supply voltage range

repetitive peak output current

non repetitive peak output current

total power dissipation

TDA7073A

TDA7073AT

Tstg storage temperature range

Tvj virtual junction temperature

Tsc short-circuit time

CONDITIONS

Tamb < 25 °C

Tamb < 25 °C

see note 1

MIN.

−

−

−

MAX. UNIT

18 V

1A

1.5 A

− 2.5 W

− 1.32 W

−55 +150 °C

− 150 °C

− 1 hr

Note

1. The outputs can be short-circuited over the load, to the supply and to ground at all input conditions.

THERMAL CHARACTERISTICS

SYMBOL

PARAMETER

Rth (j-a)

from junction to ambient

TDA7073A

TDA7073AT

CONDITIONS

in free air; note 1

in free air; note 2

VALUE

50

95

UNIT

K/W

K/W

Notes

1. TDA7073A: VP = 5 V; RL = 8 Ω; The typical voltage swing = 5.8 V and Vloss is 2.1 V therefore IO = 0.36 A and

Ptot = 2 × 0.76 W = 1.52 W; Tamb (max) = 150 − 1.52 × 50 = 74 °C.

2. TDA7073AT: VP = 5 V; RL = 16 Ω; typical voltage swing = 5.8 V and Vloss is 2.1 V therefore IO = 0.18 A and

Ptot = 2 × 0.38 W = 0.76 W; Tamb (max) = 150 − 0.76 × 95 = 77 °C.

1999 Aug 30

5

5 Page

Philips Semiconductors

Dual BTL power driver

Product specification

TDA7073A; TDA7073AT

SOLDERING

Introduction

This text gives a very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our “Data Handbook IC26; Integrated Circuit Packages”

(document order number 9398 652 90011).

There is no soldering method that is ideal for all IC

packages. Wave soldering is often preferred when

through-hole and surface mount components are mixed on

one printed-circuit board. However, wave soldering is not

always suitable for surface mount ICs, or for printed-circuit

boards with high population densities. In these situations

reflow soldering is often used.

Through-hole mount packages

SOLDERING BY DIPPING OR BY SOLDER WAVE

The maximum permissible temperature of the solder is

260 °C; solder at this temperature must not be in contact

with the joints for more than 5 seconds. The total contact

time of successive solder waves must not exceed

5 seconds.

The device may be mounted up to the seating plane, but

the temperature of the plastic body must not exceed the

specified maximum storage temperature (Tstg(max)). If the

printed-circuit board has been pre-heated, forced cooling

may be necessary immediately after soldering to keep the

temperature within the permissible limit.

MANUAL SOLDERING

Apply the soldering iron (24 V or less) to the lead(s) of the

package, either below the seating plane or not more than

2 mm above it. If the temperature of the soldering iron bit

is less than 300 °C it may remain in contact for up to

10 seconds. If the bit temperature is between

300 and 400 °C, contact may be up to 5 seconds.

Surface mount packages

REFLOW SOLDERING

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

to the printed-circuit board by screen printing, stencilling or

pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example,

infrared/convection heating in a conveyor type oven.

Throughput times (preheating, soldering and cooling) vary

between 100 and 200 seconds depending on heating

method.

Typical reflow peak temperatures range from

215 to 250 °C. The top-surface temperature of the

packages should preferable be kept below 230 °C.

WAVE SOLDERING

Conventional single wave soldering is not recommended

for surface mount devices (SMDs) or printed-circuit boards

with a high component density, as solder bridging and

non-wetting can present major problems.

To overcome these problems the double-wave soldering

method was specifically developed.

If wave soldering is used the following conditions must be

observed for optimal results:

• Use a double-wave soldering method comprising a

turbulent wave with high upward pressure followed by a

smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint

longitudinal axis is preferred to be parallel to the

transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis

must be parallel to the transport direction of the

printed-circuit board.

The footprint must incorporate solder thieves at the

downstream end.

• For packages with leads on four sides, the footprint must

be placed at a 45° angle to the transport direction of the

printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

MANUAL SOLDERING

Fix the component by first soldering two

diagonally-opposite end leads. Use a low voltage (24 V or

less) soldering iron applied to the flat part of the lead.

Contact time must be limited to 10 seconds at up to

300 °C.

When using a dedicated tool, all other leads can be

soldered in one operation within 2 to 5 seconds between

270 and 320 °C.

1999 Aug 30

11

11 Page | ||

| Páginas | Total 16 Páginas | |

| PDF Descargar | [ Datasheet TDA7073.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| TDA7072 | Single BTL power driver | NXP Semiconductors |

| TDA7072A | Single BTL power driver | NXP Semiconductors |

| TDA7072AT | Single BTL power driver | NXP Semiconductors |

| TDA7073 | Dual BTL power driver | NXP Semiconductors |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |