|

|

PDF HLMP-D401 Data sheet ( Hoja de datos )

| Número de pieza | HLMP-D401 | |

| Descripción | LED Lamps | |

| Fabricantes | AVAGO | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de HLMP-D401 (archivo pdf) en la parte inferior de esta página. Total 11 Páginas | ||

|

No Preview Available !

HLMP-3301, HLMP-3401, HLMP-3507, HLMP-3762,

HLMP-3862, HLMP-3962, HLMP-D401

T-13/4 (5 mm) Diffused LED Lamps

Data Sheet

Description

This family of T-13/4 tinted, diffused LED lamps is

widely used in general purpose indicator applications.

Diffusants, tints, and optical design are balanced to yield

superior light output and wide viewing angles. Several

intensity choices are available in each color for increased

design flexibility.

Device Selection Guide

Material/Color Part Number

GaP HER

GaP Yellow

GaP Orange

GaP Green

HLMP-3301

HLMP-3301-D00xx

HLMP-3301-F00xx

HLMP-3301-FG0xx

HLMP-3762

HLMP-3762-G00xx

HLMP-3401

HLMP-3401-E00xx

HLMP-3862

HLMP-D401

HLMP-D401-EF0xx

HLMP-3507

HLMP-3507-D00xx

HLMP-3507-EF0xx

HLMP-3962

HLMP-3962-F00xx

Luminous Intensity,

Iv (mcd) at 10mA

Min. Max.

6.1 -

2.4 -

6.1 -

6.1 15.5

9.7 -

9.7 -

6.5 -

6.5 -

10.3 -

6.1 -

3.8 9.7

4.7 -

4.7 -

7.6 19.1

12.0 -

12.0 -

Features

• High intensity

• Choice of 4 bright colors

– High Efficiency Red

– Orange

– Yellow

– High Performance Green

• Popular T-13/4 diameter package

• Selected minimum intensities

• Wide viewing angle

• General purpose leads

• Reliable and rugged

• Available on tape and reel

1 page

T-13/4 High Efficiency Red, Orange Diffused Lamps

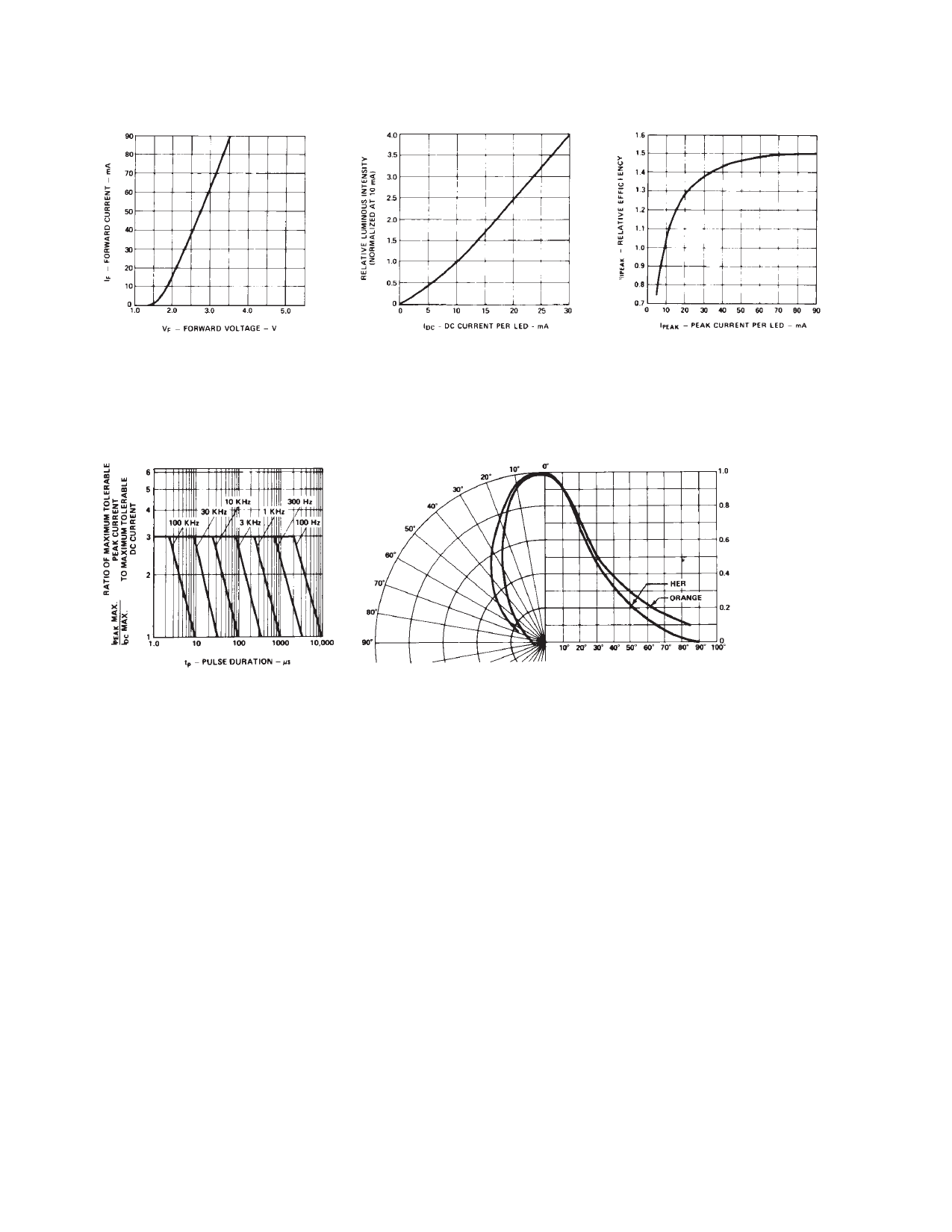

Figure 2. Forward current vs. forward voltage

characteristics

Figure 3. Relative luminous intensity vs.

DC forward current

Figure 4. Relative efficiency (luminous intensity per

unit current) vs. peak LED current

Figure 5. Maximum tolerable peak current vs.

pulse duration. (IDC MAX as per MAX ratings)

Figure 6. Relative luminous intensity vs. angular displacement

5

5 Page

Precautions

Lead Forming

• The leads of an LED lamp may be preformed or cut to

length prior to insertion and soldering into PC board.

• Ifleadformingisrequiredbeforesoldering,caremustbe

taken to avoid any excessive mechanical stress induced

to LED package. Otherwise, cut the leads of LED to length

after soldering process at room temperature.The solder

joint formed will absorb the mechanical stress of the

lead cutting from traveling to the LED chip die attach

and wirebond.

• It is recommended that tooling made to precisely form

and cut the leads to length rather than rely upon hand

operation.

Soldering Conditions

• Care must be taken during PCB assembly and soldering

process to prevent damage to LED component.

• The closest LED is allowed to solder on board is 1.59

mmbelowthebody(encapsulantepoxy)forthoseparts

without standoff.

• Wave soldering parameter must be set and maintained

according to recommended temperature and dwell time

in the solder wave. Customer is advised to periodically

check on the soldering profile to ensure the soldering

profile used is always conforming to recommended

soldering condition.

• If necessary, use fixture to hold the LED component

in proper orientation with respect to the PCB during

soldering process.

• Properhandlingisimperativetoavoidexcessivethermal

stresses to LED components when heated. Therefore,

the soldered PCB must be allowed to cool to room

temperature, 25°C, before handling.

• Special attention must be given to board fabrication,

solder masking, surface plating and lead holes size and

component orientation to assure solderability.

• Recommended PC board plated through hole sizes for

LED component leads:

• Recommended soldering conditions:

Pre-heat Temperature

Pre-heat Time

Peak Temperature

Dwell Time

Wave Soldering

105 °C Max.

30 sec Max.

250 °C Max.

3 sec Max.

Manual Solder

Dipping

–

–

260 °C Max.

5 sec Max.

LED Component

Lead Size

Diagonal

Plated Through-

Hole Diameter

Lead size (typ.) 0.45 × 0.45 mm 0.636 mm 0.98 to 1.08 mm

(0.018 × 0.018 in.) (0.025 in) (0.039 to 0.043 in)

Dambar shear- 0.65 mm

off area (max.) (0.026 in)

0.919 mm

(0.036 in)

Lead size (typ.) 0.50 × 0.50 mm 0.707 mm 1.05 to 1.15 mm

(0.020 × 0.020 in.) (0.028 in) (0.041 to 0.045 in)

Dambar shear- 0.70 mm

off area (max.) (0.028 in)

0.99 mm

(0.039 in)

Note: Refer to application note AN1027 for more information on

soldering LED components.

TURBULENT WAVE

250

200

LAMINAR WAVE

HOT AIR KNIFE

BOTTOM SIDE

OF PC BOARD

TOP SIDE OF

PC BOARD

150

FLUXING

100

50

30 PREHEAT

CONVEYOR SPEED = 1.83 M/MIN (6 FT/MIN)

PREHEAT SETTING = 150C (100C PCB)

SOLDER WAVE TEMPERATURE = 245C

AIR KNIFE AIR TEMPERATURE = 390C

AIR KNIFE DISTANCE = 1.91 mm (0.25 IN.)

AIR KNIFE ANGLE = 40

SOLDER: SN63; FLUX: RMA

NOTE: ALLOW FOR BOARDS TO BE

SUFFICIENTLY COOLED BEFORE EXERTING

MECHANICAL FORCE.

0 10 20 30 40 50 60 70 80 90 100

TIME – SECONDS

Figure 17. Recommended wave soldering profile

For product information and a complete list of distributors, please go to our website: www.avagotech.com

Avago, Avago Technologies, and the A logo are trademarks of Avago Technologies in the United States and other countries.

Data subject to change. Copyright © 2005-2015 Avago Technologies. All rights reserved. Obsoletes 5989-4258EN

AV02-1558EN - March 30, 2015

11 Page | ||

| Páginas | Total 11 Páginas | |

| PDF Descargar | [ Datasheet HLMP-D401.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| HLMP-D400 | T-1 3/4 5mm SOLID STATE LAMPS | Fairchild Semiconductor |

| HLMP-D400 | T-1 3/4 (5mm) SOLID STATE LAMPS | QT Optoelectronics |

| HLMP-D400 | LED Lamps | HP |

| HLMP-D401 | T-1 3/4 5mm SOLID STATE LAMPS | Fairchild Semiconductor |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |